Mortar is the material used in bedding,

jointing and pointing bricks and blocks in masonry walling

Constituents of mortar - Mortar

is composed of:-

·

Binding material

(cement, lime, clay, gypsum, plaster of Paris)

·

Fine aggregate

·

Water

Additives are sometimes mixed to mortar

to improve its properties.

Other forms - Fine

aggregates mixed with binding material and water also forms some important

building finishes such as Plaster, Rendering.

Materials for mortar - General

purpose mortar can consist of Sand, Ordinary Portland cement, Water,

Plasticizer, Retarder, Accelerator, Pigments or coloring agents and Hydrated

lime. Hydrated lime was once commonly used as a binder for mortar but it is

rarely used today.

Requirements of a mortar mix –

A good mortar mix should have:

·

Adequate compressive

strength.

·

Adequate bond strength

between mortar and bricks.

·

Durability – resistance

to frost and chemical attack.

·

Joints sealed against

wind-driven rain.

·

An attractive

appearance.

The ability of the mortar to meet these

requirements will depend upon the Materials specified for the mix, Workmanship

of the bricklayer, Protection of the materials and brickwork against adverse

weather.

Mix Proportions - Before

mortar can be mixed, the ingredients have to be measured in their correct

proportions. The ingredients can be measured by: Volume or by Weight. Volume mixing can be

carried out by hand or by machine, while weight mixing can only be carried out

by machine.

Methods

of Volume mixing

Materials calculated by volume should be

accurately gauged or measured into the correct quantities for each specified

mix. The methods used are- Measuring by shovel, Measuring by bucket (or pan)

and Measuring by gauge box

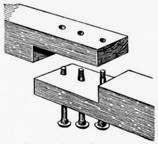

Standard Gauge Box

The internal dimensions of a gauge box

should be:-

400

x 350 x 250 mm = 0.035 m³

0.035 m³ is the volume of a bag of

cement weighing 50 kg.

Mixing by Weight

By using a weight batch mixer, the

weight of the aggregate is recorded as it is shoveled into the hopper. This is

a more accurate method of batching materials than any of the previously

described methods. The materials can be loaded into the hopper while the

previously batched materials are being mixed. The weight of materials can be

read on a dial by the operator who controls the weight, based on previous

calculations for the constituent weights for the required mix. Water is added

in liters (1 liter weighing 1kg), after calculating the requirement.

Mixing time - Mixing

time depends on the method of mixing - Machine Mixing or Hand Mixing.

Machine Mixing - In general terms, the

time of machine mixing should be between two and three minutes. On no account

should the mix be allowed to stay in the machine longer because the materials

will start to segregate

A

concrete and mortar mixer

Cleaning the mixer – It

is very important to clean the mixer after day’s work to prevent remnants of

mortar or concrete setting and sticking into the inner parts of the mixer.

Un-cleaned mixers should not be left overnight. After mixing some sand, coarse

aggregate and water should be loaded into the mixer and the mixer turned for

about 5 min. This will remove all cement/mortar/concrete stuck onto the blades

and the drum thus maintaining a clean machine.

After cleaning the machine should be

stored under cover on an elevated level to protect from elements and provide

drainage.

Hand mixing

This should take as long as required to

ensure that all the particles have been completely integrated together. A high

degree of agitation is required when hand-mixing, to ensure that any added

plasticizer etc has the necessary effect. Mixed mortar should never be

‘re-tempered’ or ‘knocked up’ with added water because this dilutes the

cement/lime element of the mortar which will result in a weaker mix. Mortar is

a mixture of the following materials in different combinations:

Sand + Cement + Water

Sand + Lime + water

Sand + Lime + Cement + Water

Sand + Cement + Plasticizer +

Water

Typical Mortar Mixes

In work sites, mortar is possibly the

least understood and most abused material on the building site. The design

strength of the mortar should be determined mainly by the strength of the brick

or block to be bedded in it. The mortar strength should roughly match that of

the brick or block and in no case should it be stronger than it.

Workability

Mortar will work more easily if the mix

contains lime. The more lime the mix contains, the more workable it will be. If

the mortar contains cement, it will stiffen more quickly, therefore the more

cement within the mix the quicker it will stiffen and set. When mortar of high

strength is required, the mix should be composed of cement and sand only.

Design of Mortar Mixes

Mortar mixes are designed to suit

certain building requirements. The chart below shows the different mixes and

their designated uses which range from 1 to 4. As the mixes progress through

the designations of 1 to 4, they become progressively weaker, but with higher

lime content they become more tolerant to structural movement.

Designation

|

Cement, lime with sand

|

Masonry Cement, sand

|

Cement, sand with plasticizer

|

Intended use

|

1

|

1:1/4:3

|

Class

A engineering bricks and dense concrete blocks

|

||

2

|

1:1/2:4:4

|

1:21/2

to 31/2

|

1:3

or 4

|

Class

B engineering bricks

|

3

|

1:1:5

or 6

|

1:4

or 5

|

1:5

to 6

|

Bricks

and blocks below DPC level

|

4

|

1:2:8

or 9

|

1:51/2

to 61/2

|

1:7

to 8

|

Bricks

and blocks above DPC level

|

Concrete mixes - Concrete

mixes are identified in two methods:

1. By

the proportions in which the raw materials are mixed – 1:2:4 (20mm). (1 part

cement + 2 parts Fine Aggregate + 4 parts Coarse Aggregate. 20mm denotes the

maximum particle size of coarse aggregate). Identifying concrete by this method

has disadvantages.

The

mix proportion does not specify required strength of concrete and has no

control over the quality of concrete.

To

overcome this modern day concrete mixes are identified by strength.

2. Concrete

mix by strength - Mixes are identified by

the strength which the concrete should possess on setting. These mixes are

called Graded Concrete mixes.

Example

s –

Grade

10 concrete (strength 10 mpa)

Grade

15 concrete (strength 15 mpa)

Grade

20 concrete etc. (strength 20 mpa)

Concrete mixes and material

requirements for a 50kg bag of cement:

Mix

|

Quantities per 50 kg bag of

cement

|

Use

|

||

Fine aggregate (m³)

|

Coarse aggregate (m³

|

App water content (liters)

|

||

1:1:2

|

0.035

|

0.070

|

20

|

Very strong water tight concrete

|

1:11/2:3

|

0.053

|

0.105

|

22.5

|

Do

|

1:2:4

|

0.070

|

0.140

|

25

|

Reinforced concrete for floor slabs,

columns, beams etc

|

1:3:6

|

0.105

|

0.280

|

35

|

Foundations, screeds

|

1:4:8

|

0.140

|

0.280

|

40

|

Fillings

|

.jpg)

.jpg)