Timber joints are used to join timber parts in a structure. Timber needs to be joined in 03 positions when making timber structures:

1.

Lengthening

2.

Widening

3.

Angled or Cross

Halving Joints

A halved joint is formed by removing

material from each at the point of intersection so that they overlap. The two

members can be joined either on the flat or on the edge. When joined on the

flat it is termed a lap joint.

The simple halved joint is created by cutting a slot

in opposite edges of the members to be joined so that they slip together. Most

commonly, the amount of material removed is equal to half the width of the

members being joined, although this depends on the relative dimensions of the

members. This joint is relatively weak and prone to splitting, due to the lack

of shoulders which would otherwise prevent twisting. When extra strength is

required, a strengthened version of the joint is called for. This involves a

more elaborate cut out which incorporates shoulders to prevent twisting of the

joint.

End Lap Joint Tapered

end lap joint

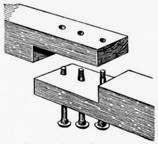

Halving joint with bolts Angled

halving joint

Cross halving joint Dovetailed cross halving Oblique halving

Mortise

&Tenon Joints

The

mortise and tenon joint is one of the oldest timber joints. This joint

is used to join pieces of wood, mainly when the adjoining pieces connect at an

angle of 90°. In its basic form it is both simple and strong. Although there

are many joint variations, the basic mortise and tenon comprises two

components: the mortise hole (female) and the tenon (male). A mortise is

a cavity cut into a timber to receive a tenon. The mortise is usually 1/3

thickness of the member. A tenon is a projection on the end of a timber

for insertion into a mortise. Usually the tenon is longer than it is wide. The

tenon, formed on the end of a member generally referred to as a rail, is

inserted into a square or rectangular hole cut into the corresponding member.

The tenon is cut to fit the mortise hole exactly and usually has shoulders that

seat when the joint fully enters the mortise hole. The joint may be glued,

pinned, or wedged to lock it in place.

Haunched Mortise &Tenon Wedged Mortise

&Tenon

Bridle joint

Bridle joint is similar to mortise &tenon, in

that a tenon is cut on the end of one member and a mortise is cut into the

other to accept it. The distinguishing feature is that the tenon and the

mortise are cut to the full width of the tenon member. The corner bridle

joint (also known as a slot mortise and tenon) joins two members at

their respective ends, forming a corner. This form of the joint is commonly

used to house a rail in uprights, such as legs. It provides good strength in

compression and is fairly resistant to Stacking, although a mechanical fastener

or pin is often required. Corner bridles are often used to join frame

components when the frame is to be shaped. Material can be removed from the

joined members after assembly without sacrificing joint integrity.

A variation of the bridle joint is the T-bridle,

which joins the end of one member to the middle of another.

Corner

Bridle Joint

‘T’

Bridle joint.

Timber products.

Timber products are the structural or

non-structural items made out of wood. These are widely used for construction

items and house furniture and fittings. The examples are numerous:

1 1. Doors

2. Windows

3. Stairs

4. Tables

5. Cupboards

6. Roofs

7. Partitions

8. Floors

2. Windows

3. Stairs

4. Tables

5. Cupboards

6. Roofs

7. Partitions

8. Floors

Door Window Stair

Table Cupboard

Timber

Roof Timber

Partition

.jpg)

0 comments:

Post a Comment